Hybrid Services recently announced two new high-end flatbeds LED UV printers from Mimaki. These will arrive with us later this year, but in the meantime, it’s a great opportunity to reflect on how we’ve got here.

With Mimaki’s first standout flatbed printer shown at IPEX 2006 it was quite an entrance for the company best known for its groundbreaking textile, solvent and aqueous models. With a pioneering small format UV printer launched a year or two previous, Mimaki already had some traction in the sector, therefore their reputation was steadily improving for exceptionally high print quality at a time where UV printer output was not renowned for its high definition.

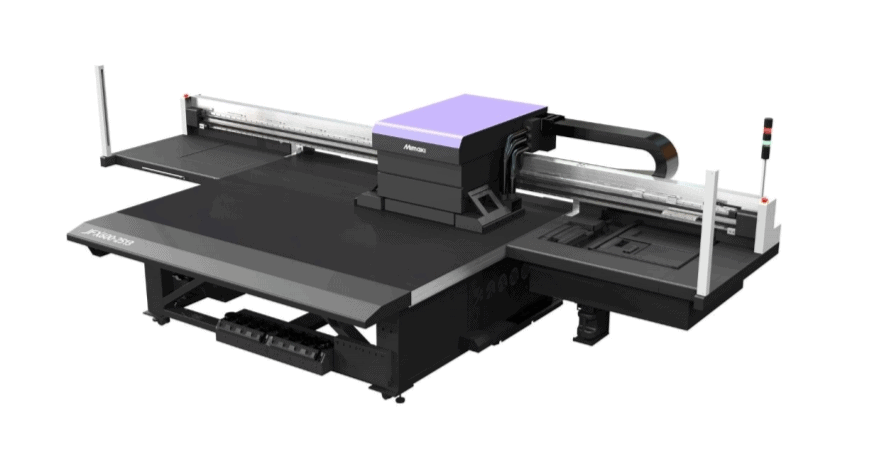

The following years delivered generation after generation of improvements across every aspect of the technology. Consistently upping the productivity, quality and ease of use with each launch, a pivotal and comparatively recent release was the JFX200-2513; an 8’ x 4’ LED UV cure flatbed that swiftly became the biggest selling model on the market.

Mimaki has built its UV flatbed and roll-to-roll ranges around the cold cure lamp technology for well over a decade, proving its quality and reliability. With considerable eco, production and cost saving benefits, what is now considered the norm was developed extensively by Mimaki at a time when almost every other manufacturer persisted with expensive and unwieldy metal halide lamps. For example Mimaki’s forward-thinking approach to product design, we now see the Japanese manufacturer embracing Industry 4.0 with significant focus on robotics, automation and other technologies designed to reduce human intervention, maximise productivity and minimise wasted time and materials.

The new JFX600-2513 is capable of printing an 8’ x 4’ board in under a minute, the productivity pinch points cease to be the print element, hence the focus from Mimaki on investigating other areas of the process such as communicating with loading and unloading robotics. Headline speeds aren’t the only reason for the interest and anticipation around the new JFX550 and 600 models though; with an unparalleled ink range, their suitability for almost every conceivable UV printing application is guaranteed, with 5 different levels of flexible inks available for each of the new JFX additions.

In real-world terms, this means the optimum ink can be specified to suit a print company’s target work, so for businesses focussed on rigid signage, the durable and scratch-resistant LH100 ink may be most suitable, whereas a business specialising in printing onto more pliable substrates would benefit from an ink such as Mimaki’s LUS-150 option, that contains a high degree of flexibility.

The ability to choose not just inks, but bed size and productivity requirements means Mimaki’s comprehensive flatbed range (that extends from A3 models right up to 10’ x 5’ solutions) offers an unparalleled choice that ensures businesses can specify the most appropriate system for their needs, that’s still scalable and flexible enough to adapt should they evolve. The arrival of the new JFX550 and JFX600 give us very specific solutions at the sharp end of the range, but the technology found on the new high production models rapidly cascades down to the rest of the line-up, with the A3 and A2 UJFs sporting features found on previous high-end industrial solutions.

If you would like to know more about these upcoming machines, please contact us on info@yourprintspecialists.co.uk.