What is DTF Printing?

"DTF printing" or "Direct-to-Film printing" is a relatively new digital printing technology that allows users to print directly onto a heat transfer film. This process involves printing the design using a specialised ink and then transferring it onto the garment using a heat press machine.

DTF printing is a popular method for custom apparel printing because it offers high-quality, vibrant prints with excellent durability. It is often used for printing designs onto dark-colour garments or for printing intricate designs that cannot be achieved using other printing methods.

Compared to traditional screen printing, DTF printing is faster and more cost-effective for small production runs, and it does not require the use of screens or chemicals.

What is the process for DTF printing?

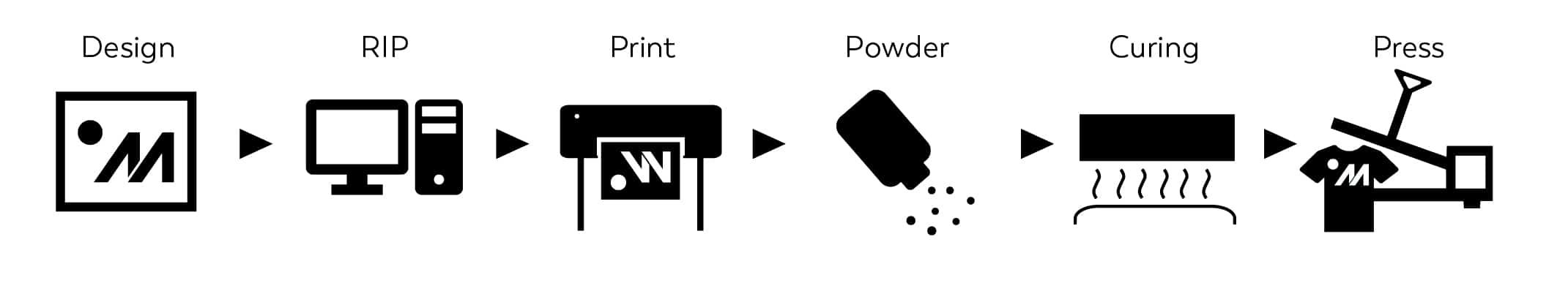

The process for DTF printing involves several steps. Let's take a look at how to create a DTF transfer print.

Design creation: The first step is to create the design that you want to print using design software such as Adobe Illustrator or CorelDRAW. Once the design is created, it is exported as a high-resolution image file, such as a PNG or JPEG.

Printing the design: The next step is to print the design onto the heat transfer film using a specialized DTF printer such as the Mimaki TxF150-75. This then needs the glue powder applied. This can be done manually or automatically via an integrated shaker and oven system. The oven heats the powder to form the glue that allows the application to the garment.

Preparing the garment: The garment is prepared for printing by ensuring that it is clean and flat. The garment is then placed onto the heat press machine.

Applying the film: The printed film is placed onto the garment with the design facing up. The heat press machine is then used to apply heat and pressure to transfer the design from the film onto the garment. The heat and pressure cause the glue to bond with the fibres of the fabric.

Removing the film: Once the transfer is complete, the film is removed from the garment. The finished product is now ready for use.

What can you use DTF printing for?

DTF printing can be used for a variety of applications, including:

Custom apparel: DTF printing is a popular method for printing custom designs onto t-shirts, hoodies, and other garments. It is an excellent choice for printing designs with multiple colours, gradients, and fine details.

Promotional products: DTF printing can be used to print designs onto promotional products such as bags, hats, and phone cases. It is a versatile printing method that can be used on various materials.

Team uniforms: DTF printing is a great option for printing numbers, logos, and names onto team uniforms. It is a durable printing method that can withstand repeated washings and wear.

Personalised gifts: DTF printing can be used to create personalised gifts such as mugs, keychains, and mousepads.

Overall, DTF printing is a versatile printing method that can be used for various applications, and it offers high-quality, vibrant prints with excellent durability.

What equipment do I need for DTF printing?

To perform DTF printing, you will need the following equipment:

DTF printer: This is a specialized printer that uses a modified ink system to print directly onto heat transfer film. DTF printers are available in various sizes and can handle different types of films.

DTF ink: DTF ink is a specialized ink that is used for printing onto heat transfer film. It is different from standard ink used in DTG printing and requires a modified ink system in the printer.

Heat transfer film: This is a specialized film that is used for printing designs onto garments. The film is available in various colors and finishes, such as matte, gloss, and metallic.

Heat press machine: This is a machine that is used to transfer the design from the film onto the garment. The machine applies heat and pressure to transfer the ink from the film onto the garment.

Computer and design software: You will need a computer with design software, such as Adobe Illustrator or CorelDRAW, to create the design that you want to print onto the heat transfer film.

Overall, the cost of the equipment can vary depending on the quality and size of the equipment you choose to purchase.

DTF printing is a relatively new printing technology that has gained popularity in recent years. While it is not yet as widely used as some other printing methods, such as screen printing or DTG printing, it is becoming increasingly popular among small businesses, entrepreneurs, and individuals who are looking for a cost-effective and versatile printing method.

One reason for the growing popularity of DTF printing is its ability to print vibrant, high-quality designs on both light and dark-colored fabrics, including cotton, polyester, and blends. This makes it a popular choice for printing custom apparel, such as t-shirts, hoodies, and hats.

Additionally, DTF printing offers a range of finishes, including matte, gloss, and metallic, which can give the designs a unique and professional look. It is also a faster and more cost-effective method for printing small runs of customized items compared to traditional screen printing, which requires the creation of screens for each color in the design.

Overall, DTF printing is gaining popularity as a versatile and cost-effective method for printing custom designs onto a variety of substrates.