DISCONTINUED - PLEASE CONTACT YPS FOR MORE INFO ON ALTERNATIVE MODELS

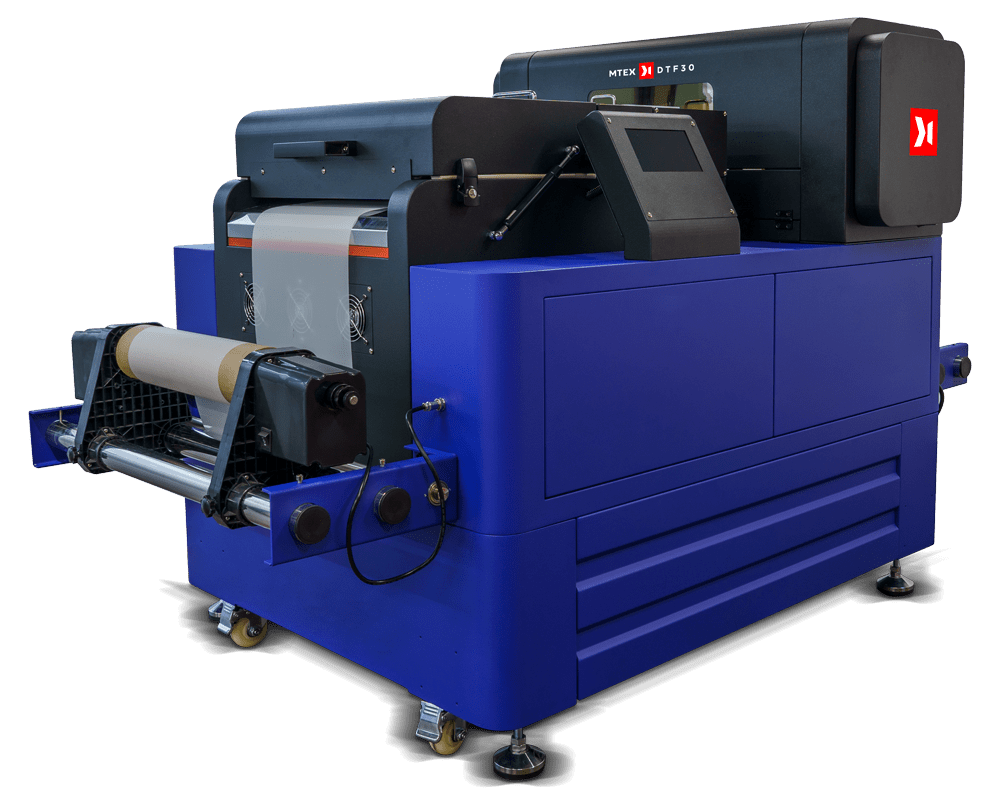

MTEX DTF 30 – Direct to Film Printer

The MTEX DTF 30 is the all in one solution for direct to film printing. Create soft touch transfers for fabric, clothing and so much more using DTF technology. This machine requires no pre or post treatment with inline printing and powder shaking as part of the all in one process.

This machine is suitable for both short runs as well as longer production runs. Pigment water based inks offer an eco friendly and sustainable print solution.

Two printheads offer faster production and high quality with CMYK and white. Having the white ink independent to the CMYK ink, allows for drying time in between resulting in a bright vivid image

Transfers created by the MTEX DTF 30 are suitable for both light and dark fabrics making this printer incredibly versatile.

Create transfers for garment decoration and more in three easy steps.

- Create your artwork using design software

- Set up machine ready for print

- Send to print, when ready cut and heat transfer to item

Width: 30cm

Enquire:

MTEX DTF 30 Specification:

- Dimensions & Weight: W: 1110 mm / D: 1235 mm / H: 1250 mm; Weight: 195 Kg

- Resolution From 360 up to 2880 DPI

- Drop Size Variable

- Ink Pigment Water Base

- Colors 5 Colors / CMYK + WHITE

- RIP MTEX RIP

- PRINT SPEED 3,5m2/h

- Power Consumption 218 Watts - 220 V / 15 A

- Operation Environment Guaranteed temperature: 15º C - 30ºC / Humidity: 35 - 65% Rh (No condensation) / Dust: Equivalent to normal office level (dust-free and well ventilated)

Your Print Specialists:

MTEX DTF 30 offers an all in one solution for direct to film printing. Create stunning, vibrant heat transfers for garment decoration and more.

What is DTF printing?

DTF printing means Direct to Film and is the process of printing directly to a carrier film. The design is printed in reverse and is backed with white ink. This is then covered with a powder which creates the adhesion required when transferring the design. Using heat, the transfer can be transferred on to both light and dark fabrics.